- Click here Or

- Call Us Now!

- 434-363-4565

Kevin Bernardo-Zamora

Service Expert

Jobs Completed by Kevin Bernardo-Zamora

See AllWaynesboro, VA

October 2, 2025

We completed our standard maintenance protocol which focuses on: 1) Safety, 2) Function and, 3) Efficiency.

In short, we clean all coils. We verify all capacitors, motors and safeties are functioning properly and we test them against manufacturer specifications. We confirm proper airflow. We verify refrigerant charge.

After the system is tuned, we return it to service.

Keswick, VA

October 1, 2025

We installed an Aprilaire Steam Humidifier to her system. At peak demand this steam humidifier can add up to 30 gallons of humidity to her home.

To ensure this system works at peak efficiency and capacity, we added a new water line with shut-off and a new, dedicated electric circuit. We completed all components and showed them how to operate it in one day.

Belvedere, VA

September 29, 2025

We confirmed availability and price since the original installer never registered the system warranty. With approval we secured the coil and returned on Monday to replace the coil.

We recovered any remaining refirgerant, tested for acid contamination, removed and replaced the filter drier and installed the new coil. Per standards, we floated dry nitrogen while brazing to prevent contamination, pressured tested and evacuated the system to confirm it was clean, dry and tight. Lastly we recharged the system with new refrigerant and returned the system to service.

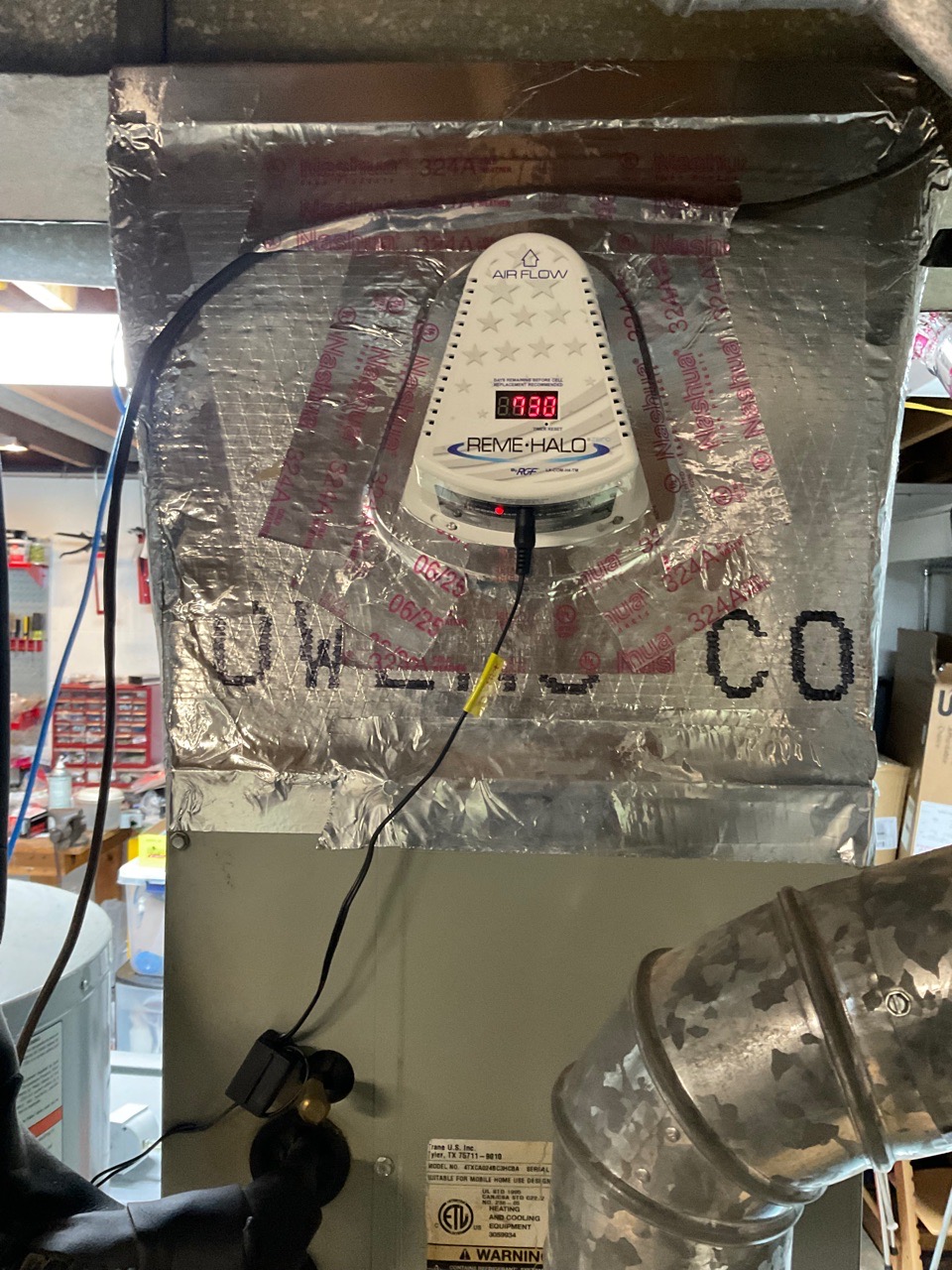

Johnson Village, VA

September 17, 2025

We installed a Reme Halo Zero, no ozone, air purifier to his system. This system uses hydrogen peroxide ions (don't hold me to explaining the science correctly) to neutralize odors, bacteria, viruses, molds and mildews inside the home. What's awesome about this product is that a Reme Halo treats the air stream not just the equipment so the benefit is felt throughout the home.

Ruckersville, VA

September 17, 2025

We completed a tune-up as planned on the systems - no major problems as these are new systems. We did find that the furnace flue and fresh air had been cut in the crawl / cellar space during a recent deck build. We turned off the gas so that the furnace cannot light - and they had heat pump heat - and designed a new path for the flue and fresh air piping. We returned with the proper mateirals and tools and completed the repair.

We returned the furnace to service and completed our combustion testing to ensure proper and safe operation.

Keswick, VA

September 15, 2025

We completed our standard fall heat pump maintenance - cleaning coils, verifying capacitor microfarads, amperage draws and voltage to motors, cleanliness of indoor blower wheel, refrigerant charge and more. We focus on safety first, then proper function, then we optimize for efficiency.

Earlysville, VA

September 15, 2025

On the main level system, we found a failed capacitor and were able to return service quickly. We also completed the fall tune-up.

The bedroom level heat pump showed a complete failure as the compressor no longer compresses so it does not deliver heating or cooling. We provided multiple repair and replacement options ranging from a new compressor, to a new outdoor condenser to complete new systems.

Stony Point, VA

September 12, 2025

Modern press tools like the RLS fitting allow us to make this repair quickly and easily vs when brazing was our only option. We removed the bad section and used a press coupling to make the repair. We replaced the filter drier (a must when a refrigerant system is exposed to atmospheric air) and then completed a pressure and evacuation test. We also replaced the missing insulation on the lineset.

During testing we discovered another leak on an original installation braze joint, which we also repaired.

Once testing was complete, we recharged the system and returned it to service.

Johnson Village, VA

September 11, 2025

Based on the limited service needs of the system, we did not recommend replacement at this time - we believe the system has several years of life left.

We did recommend a deep clean of the blower wheel, a full maintenance, replacement of the duct board return riser and adding a high-efficient media filter.

During our initial assessment, we noted how much crud had built up on the blower wheel and how dirty the duct board return riser was. We also noted the ill-fitting filter in an old filter housing which allowed dirty air to flow around the filter, causing the dirty blower wheel.

Now, John has a cleaned and tuned system, a clean blower wheel, an all metal return riser (tape sealed) and a new media filter.

Earlysville, VA

September 10, 2025

We isolated the furnace the furnace from the rest of the gas system so we could return service to the water heater and stove. We then re-built a section of gas line to the furnace so that it did not impede movement in the mechanical room / storage room, making it much easier to move in the space.

Gas safety is vitally important, so we had double isolation and tested the system for over 24 hours prior to inspection. After we passed inspection, we returned to make the final connections to the furnace before testing and commissioning the furnace.

Charlottesville, VA

September 5, 2025

We were able to schedule a call quickly and found a failed indoor motor. The unit was still covered under the standard 5 year manufacturer warranty - it had not been registered for the extended 10 year warranty - so we worked with the manufacturer to have a new motor delivered.

We had the new motor before the next weekend, and warmer weather, so we scheduled a return visit to replace the failed motor and return air conditioning.

Charlottesville, VA

September 3, 2025

We completed a combined heating and cooling maintenance after the first year of operation. So we checked heat pump operation in both modes and then checked the furnace for proper operation.

We also answered some questions and made some adjustments based on the clients' observations about the system and comfort across all levels after the first year. Specifically we made an adjustment to the basement return to improve air return from the basement.

Charlottesville, VA

September 3, 2025

We completed a fall maintenance on a ducted heat pump and investigated the cause of a noise on the outdoor ductless outdoor unit. We found a loose capacitor and secured it. Note: we had deep cleaned the ductless system over the summer so we did not repeat a cleaning at this time.

Charlottesville, VA

June 18, 2025

In our initial fall visits, we diagnosed an overcharge of refrigerant and improper airflow. We recovered some charge and adjusted airflow and saw improvement. Then the weather shifted and it functioned as expected in heat mode.

So we paused - until the compressor died. We replaced the compressor and charged the system to manufacturer specifications and it ran perfectly in heating mode. Then the heat returned and again it would not cool properly. We dug deeper and discovered that the system did not have the correct coil - unclear if it was a factory or installer fault - and we secured a correct warranty coil.

We replaced the faulty coil and the system functions perfectly - even in extreme, record-breaking heat. Our client is comfortable again and the system numbers we focus on are what we expect to see for a healthy system.

Charlottesville, VA

March 26, 2025

We installed a hybrid heating system combining an 80% efficient American Standard furnace with a Moovair heat pump and matched coil. This combination provides the comfort and efficiency of the heat pump as the primary AC and heat source, with the comfort of a gas furnace as the secondary source of heat for the coldest times of the year.

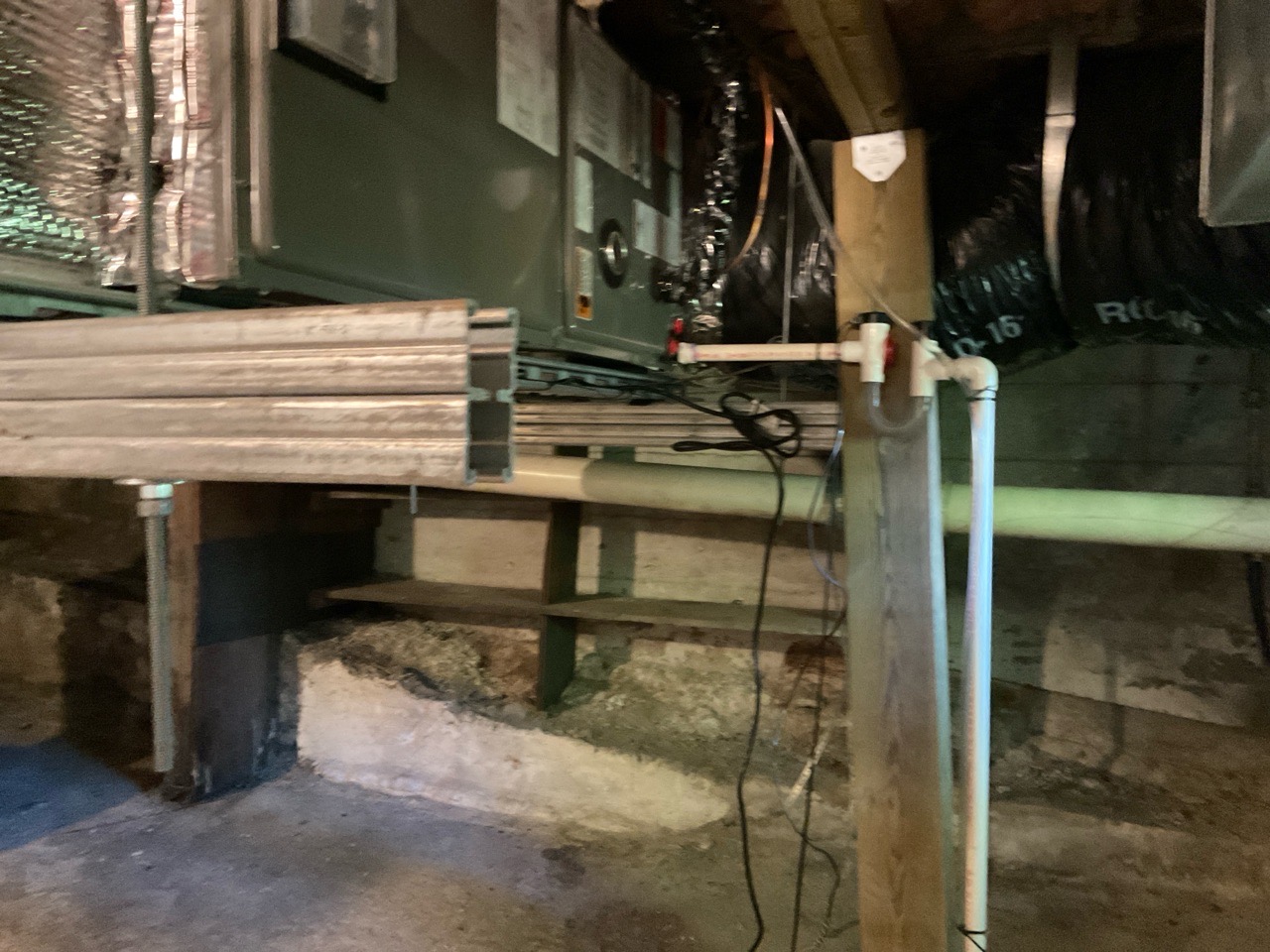

Charlottesville, VA

August 30, 2023

We offered a selection of replacement options and Trevor selected a modern American Standard furnace and air conditioner replacement. While we had the equipment out, we upgraded the air filtration system, removed some duct bottlenecks and re-sealed and re-insulated the exposed ducts. We were able to clean and reuse the lineset and the furnace vent piping. In the end we had a nice, clean replacement in a tight cellar that immediately brought comfort to Trevor's home.